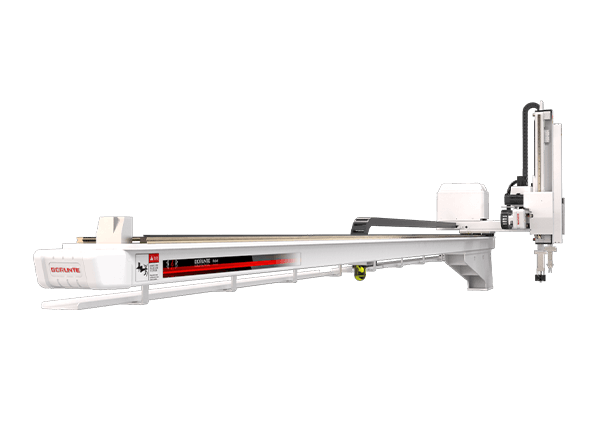

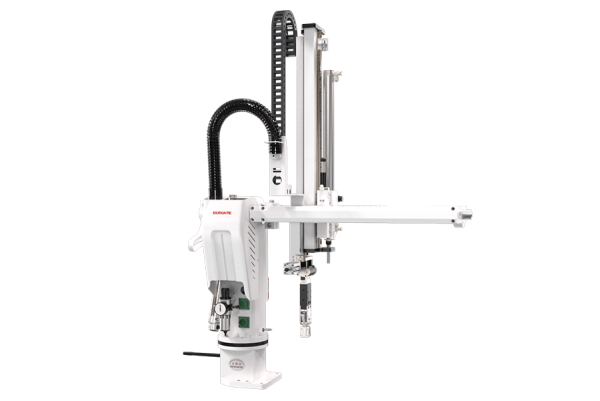

BRTP08WSS0PC

Swing-arm Manipulator

- Simple Operation

- Quick response

- Safe And Efficient

Product Introduction

BRTP08WSS0PC series applies to all types of horizontal injection machines of 150T-250T for take-out products. The up and down arm is a single/double sectional type. The up and down action, drawing part, screwing out, and screwing in of them is driven by air pressure, with high speed and high efficiency. After installing this robot, productivity will be increased by 10-30% and will reduce the defective rate of products, ensure the safety of operators, reduce manpower and accurately control the output to reduce waste.

Accurate positioning

Fast

Long service life

Low failure rate

Reduce labor

Telecomm unication

Basic Parameters

| Power Source (kVA) | Recommended I.M.M (ton) | Traverse Driven | Model of EOAT |

| 0.06 | 150T-250T | Cylinder drive | zero suctions zero fixtures |

| Traverse Stroke (mm) | Crosswise Stroke (mm) | Vertical Stroke (mm) | Max.loading (kg) |

| / | 300 | 850 | 2 |

| Dry Take Out Time (sec) | Dry Cycle Time (sec) | Air Consumption (NI/cycle) | Weight (kg) |

| 2 | 6 | 3 | 60 |

Model representation: I:Single cut type. W:Telescopic type. S:Product arm. S0:Driven by cylinder(Traverse-axis).

The above-mentioned cycle time are the results of our company's internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

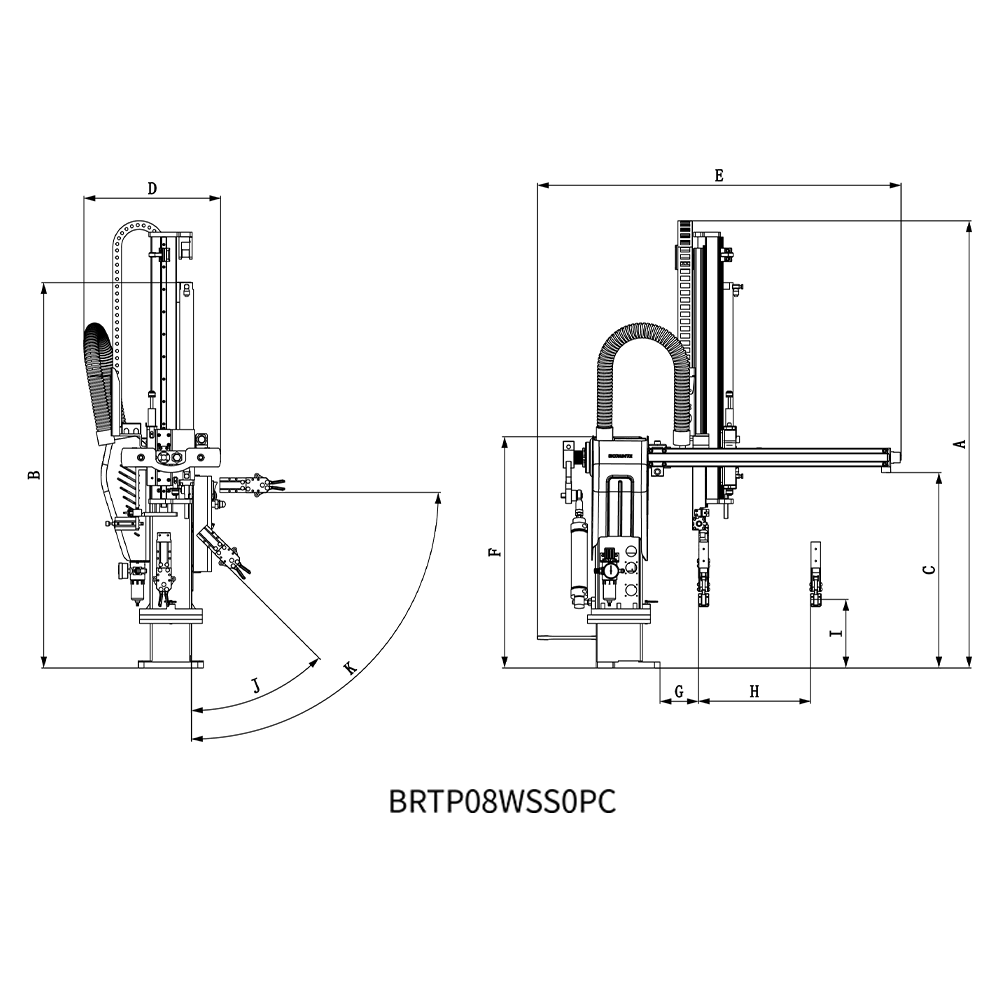

trajectory chart

| A | B | C | D | E | F | G |

| 1205 | 1031 | 523 | 370 | 972 | 619 | 102 |

| H | I | J | K | |||

| 300 | 180 | 45° | 90° |

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.

Precautions for Storage and Handling Caution:

Do not store or place the machine in the following environment, otherwise it may cause fire, electric shock or machine damage.

1. Places exposed to direct sunlight, places where the ambient temperature exceeds the storage temperature conditions, places where the relative humidity exceeds the storage humidity, or places with large temperature differences or condensation.

2. Places close to corrosive gas or flammable gas, places with a lot of dust, salt and metal dust, places where water, oil and medicine drip, and places where vibration or shock can be transmitted to the subject. Please do not grab the cable for transportation, otherwise it will cause damage or failure of the machine.

3. Do not stack too much products on the machine, otherwise it may case machine damage or failure.